Needle Valve Manufacturer

NTGD Needle Valve, Your Needle Valve Manufacturer of Proven Quality & Trustworthy Service

Needle Valve Manufacturer Based in China

NTGD needle valve company is an ISO9001 certified needle valve manufacturer who is located in China. Our products range from needle valve, needle globe valve, thermal instrument valve and valve group. NTGD needle valve have various types, novel structure, good strength and sealing. NTG can also manufacture to the drawing or on-site design for the production of chemical, electric power, municipal, nuclear power, metallurgy, machinery, pharmaceutical, aviation and other industrial automatic control pipeline system

Needle Valve

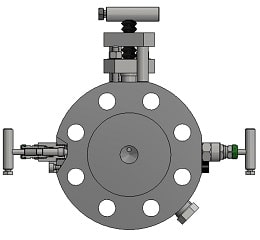

NPT Needle Valve | Weld Needle Valve | Flange Needle Valve | Ferrule Needle Valve

Manifold

Two Valve Manifold | Three Valve Manifold | Five Valve Manifold

Ask Us About Our Needle Valve

At NTGD needle Valve, we manufacture variety of needle valve. Request a free quote from us today!

Featured Needle Valve

Industries That We Serve

- Needle valves are widely employed to regulate flow and protect sensitive gauges from damage caused by liquid and gas pressure surges. They’re suitable for systems with lower flow rates and lighter, less viscous materials.

- Needle valves are commonly found in low-pressure hydraulic systems, chemical processing, and other gas and liquid applications. Because of the materials used, these valves may be used in high-temperature and oxygen applications.

- Stainless steel, bronze, brass, or metal alloys are commonly used for needle valves. Therefore, it’s critical to select a needle valve made of the appropriate material for the job at hand. This will extend the life of the valve and keep your systems functioning smoothly and safely.

Never Compromised on Quality

Since its establishment, NTGD needle valve has always attached importance to product quality and strengthened management system. Over the years, we have actively advocated the enterprise spirit of “quality is life, reputation is the soul of the enterprise”, and adhered to the enterprise tenet of “integrity-based, customer first” to better serve clients. We will, as always, focus on product quality and actively improve the enterprise management system.

Our Mission

NTGD needle valve aim to be your needle valve expert of proven quality and trustworthy partner, We adopt the latest technology to take the product quality to the next level. NTGD continuously improves and enhances engineering designs to ensure product performance. NTGD need valve always strive to establish itself to be an important needle valve manufacturer in the marke . We hope our needle valve connect the pipe as well as long term relationship between us.

Certified

As long as we estblish NTGD needle valve, we applied for ISO 9001 certificate to establish our quality system. We have been certified for more than 20 year span.

These years NTGD needle valve get certified by ISO 45001 and ISO 14001. These management systme help us continuously improve quality.

What is a needle valve

Needle valves and shutoff valves are almost similar but designed differently. They are used to start, stop, and control the flow rate of a pipeline. As opposed to a cut-off valve, a needle valve has a long, tapered, needle-like tip at the end of the valve stem. This is commonly known as the plunger.

These valves also include a handwheel or a tiny lever on the plunger that regulates the plunger position. The needle-like plunger of the valve inserts into the seat. Because of its unique shape, a needle valve can precisely and reliably control the amount of fluid that goes through it

How does needle valve works

The operation of needle valves can be done manually or mechanically. The distance between the plunger and the valve seat is controlled by the handwheel in manually operated needle valves.

The plunger is lifted when the handwheel is moved in one direction, opening the valve, and allowing fluid to pass through. The plunger travels closer to the seat when the handwheel is moved in the opposite direction, reducing the flow rate, or closing the valve.

Automated needle valves have a hydraulic motor or an air actuator that opens and shut the valve automatically. The motor or actuator will adjust the plunger’s position in response to timers or pre-set data obtained while monitoring the machinery.

Needle Valve Selection Guide

- For the main pipeline of oil and natural gas transportation, the needle valve with full diameter and full welding structure shall be selected for the pipeline that needs to be cleaned and buried underground;

- The needle valve with flange connection is selected for the product oil transmission pipeline and storage equipment.

- In the pipeline of city gas and natural gas, the needle valve with flange connection and female thread connection is selected.

- In the oxygen pipeline system in the metallurgical system, the needle valve with strict degreasing treatment and flange connection should be selected.

- The low-temperature needle valve with valve cover should be selected for the pipeline system and device of low-temperature medium.

- Lifting rod needle valve can be used in pipeline system of FCC unit in oil refining unit.

- All stainless steel needle valve made of austenitic stainless steel with PTFE as seat sealing ring should be used in the equipment and piping system of corrosive medium such as acid and alkali in chemical system.

- Metal to metal sealing needle valve can be used in high temperature medium pipeline system or device in metallurgical system, power system, petrochemical plant and urban heating system.

- When flow adjustment is needed, worm gear driven, pneumatic or electric needle valve with V-shaped opening can be selected.

Top 5 Needle Valve Manufacturer

Company: Aalborg Instruments & Controls, Inc.

Business type: Needle Valve Manufacturer

Address: 20 Corporate Drive Orangeburg, New York 10962 USA

Phone: +1 (845) 770-3000

Products: VB barstock valves, VT PTFE needle valve, VT PTFE precision needle valves, SMV stepping motor valve

Applications: commonly used to control flow and protect delicate gauges from damage caused by sudden pressure surges of liquids and gases.

Company: Armaturen-Arndt GmbH

Busines type: Needle Valve Manufacturer

Adress: Heuserweg 16, 53842 Troisdorf, Germany

Phone: +49 2241 96390

Products: High-pressure shut-off valves, Manometer gauge valves, Needle valves, Nonreturn valves, Drain cocks

Applications: Automatic combustion control systems, For precise flow regulation, is necessary.

Company: Budenberg Gauge Company Limited

Business type: Needle Valve Manufacturer

Address: Unit B2, Altrincham Business Park, Stuart Rd, Broadheath, Altrincham WA14 5GJ, United Kingdom

Phone: +44 161 777 7300

Products: Needle Valve 1/2 inch NPT MxF, Needle Valve 1/2 inch NPT FxF, Multiport Gauge, and Gauge Vent Valve

Applications: Oil and Gas, Petrochemical, Power Generation.

Company: Generant Inc.

Business type: Needle Valve Manufacturer

Address: 1865 Route 23 South PO Box 768 Butler, NJ 07405

Phone: (973) 838-6500

Products: Integral and Screwed Bonnet Needle Valve, Forged and Bar Stock Body Needle Valve, Precision Metering Needle Valve, Metal to Metal and Soft Tipo Stem Needle Valve, Wafer Packing Needle Valve

Applications: The Series 3000 Screwed Bonnet Needle is an economical bar stock body metering valve where positive shut off and coarse metering is desired. For extremely accurate flow metering, the Series PMV offers the most precise control of fluids and gases.

Company: Indumart Inc.

Business type: Needle Valve Manufacturer

Address: 25 Denison St, Markham, ON L3R 1B5, Canada

Phone: +1 905-944-9998

Products: Needle Valve, Gauge Valves, 2-Valve Manifolds, 3-Valve Manifolds, 5-Valve Manifolds

Applications: Indumart valves and manifolds are high-pressure valves suitable for shutting off the impulse line and for mounting to pressure instruments. They are mostly used in oil, gas, chemical, petrochemical, power generation, and processing industries.